Imagina esto: un collar que brilla como oro puro, pero posee la fuerza del acero inoxidable. O una pulsera conserva su brillo y color incluso después de años de uso.. Esto es posible gracias a la magia del revestimiento PVD.. Pero, ¿qué es exactamente el recubrimiento PVD?? Este artículo le llevará al arte del recubrimiento PVD en joyería..

¿Qué es la joyería PVD??

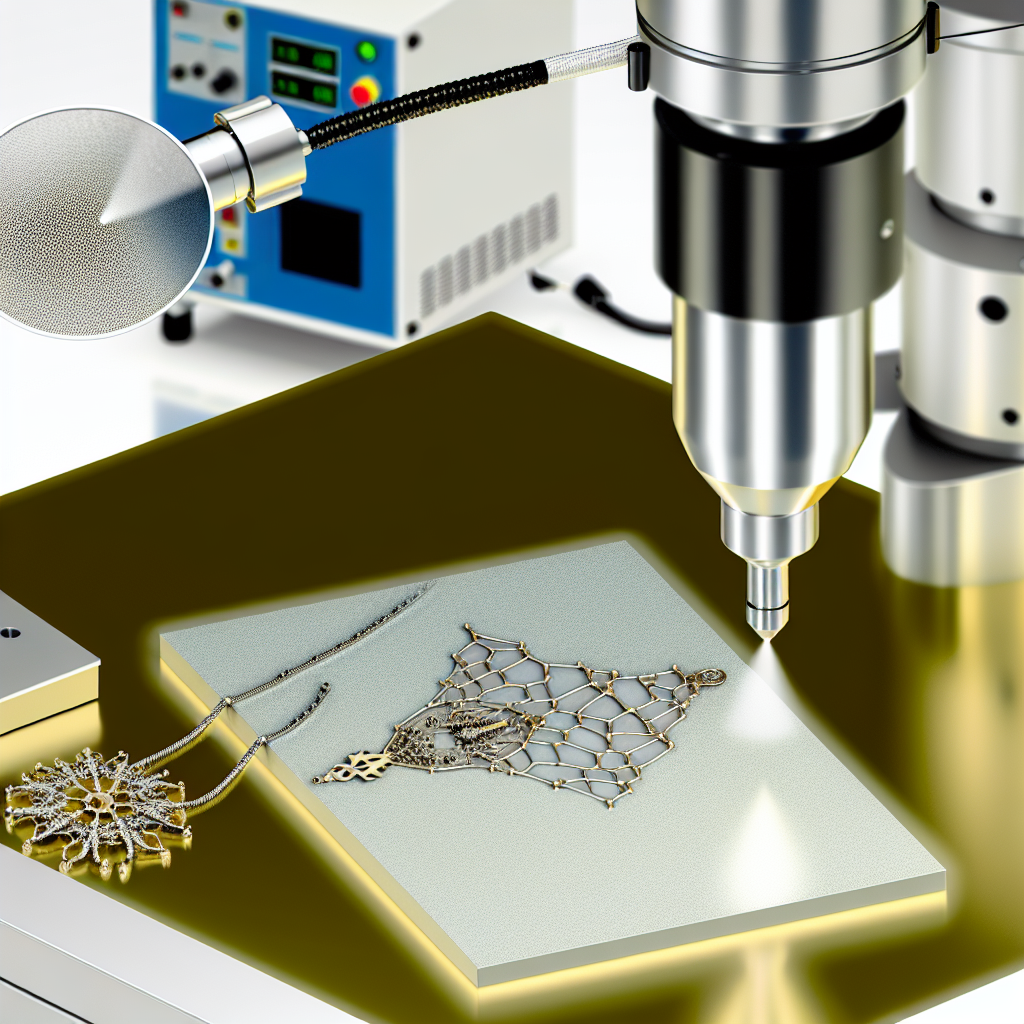

PVD, o Deposición Física de Vapor, revestimiento, o enchapar joyas es una técnica sofisticada que aplica finas capas de metal sobre la superficie de varias piezas de joyería., como titanio y acero inoxidable. Durante el proceso PVD, las joyas se colocan en una cámara de vacío, donde se depositará el metal (como el oro, oro rosa, o titanio negro) Se calienta hasta alcanzar la fase de vapor.. Una vez en la fase de vapor, Las moléculas de metal viajan a través de la cámara de vacío y se condensan en la superficie de la joyería., formando una delgada, revestimiento duradero.

Este proceso de recubrimiento ocurre a altas temperaturas y bajo baja presión., permitiendo que las partículas de metal se unan firmemente al sustrato de joyería. Como resultado, Las joyas recubiertas de PVD presentan una excelente resistencia a los arañazos, retención de color, y durabilidad. El producto final son joyas con un acabado vibrante y duradero que es a la vez estéticamente agradable y resistente al uso diario..

Según datos del sector, Las joyas recubiertas de PVD son hasta diez veces más duraderas que las joyas chapadas tradicionales.. Además, Los estudios han encontrado que las joyas de PVD conservan su color y brillo mucho más tiempo que otros métodos de recubrimiento., gracias a su capacidad para unirse molecularmente con el sustrato metálico.

Tipos comunes de recubrimiento PVD en joyería

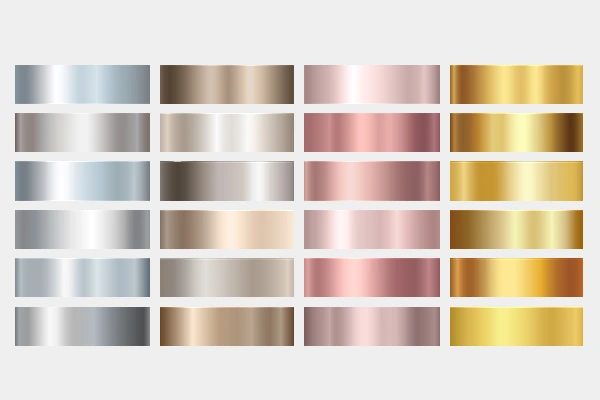

Existen varios tipos de recubrimientos PVD que se utilizan habitualmente en la fabricación de joyas., cada uno ofrece propiedades y opciones estéticas únicas. Del opulento encanto del oro al romántico rubor del oro rosa, y la audaz sofisticación del negro, cada recubrimiento puede elevar las joyas a alturas extraordinarias. Aprendamos cómo estos revestimientos transformadores redefinen el lujo y el estilo en la moda y el adorno..

¿Qué es el recubrimiento PVD dorado?

El recubrimiento PVD de oro implica depositar finas capas de oro sobre la superficie de la joyería mediante un proceso de cámara de vacío.. El oro se vaporiza en la cámara y luego se condensa en las joyas., formando un revestimiento duradero y brillante.

Beneficios: Este revestimiento realza el brillo y la calidez del oro.. A diferencia del baño de oro tradicional, Crea una capa de oro más gruesa y resistente., proporcionando una resistencia superior a los arañazos y una mayor longevidad.

¿Qué es el revestimiento PVD de oro rosa?

El revestimiento PVD de oro rosa es similar al revestimiento de PVD dorado, pero implica depositar finas capas de oro rosa sobre la superficie de la joyería mediante el proceso PVD.. El oro rosa se vaporiza y se condensa sobre el sustrato de joyería., creando un tono cálido y romántico.

Beneficios: Las joyas recubiertas de PVD en oro rosa irradian elegancia e individualidad.

¿Qué es el revestimiento PVD negro?

El recubrimiento de PVD negro implica depositar finas capas de titanio negro u otros materiales sobre la superficie de la joyería mediante el proceso de PVD.. El material se vaporiza y luego se condensa sobre el sustrato de joyería., dando como resultado un acabado negro elegante y moderno.

Beneficios: Las joyas recubiertas de PVD negro añaden un toque de misterio y sofisticación a cualquier conjunto., lo que lo convierte en uno de los favoritos entre las personas vanguardistas que buscan hacer una declaración con sus accesorios..

¿Qué es el recubrimiento PVD de plata??

El recubrimiento PVD de plata implica depositar finas capas de plata sobre la superficie de las joyas mediante el proceso PVD.. El material de plata se vaporiza y condensa sobre el sustrato de joyería., produciendo un acabado plateado clásico y atemporal.

Beneficios: A diferencia del baño de plata tradicional, El recubrimiento PVD forma una capa protectora que prolonga la vida útil de la joyería manteniendo su brillo brillante..

¿Qué es el recubrimiento PVD de metales mixtos??

El revestimiento PVD de metales mixtos combina múltiples metales, como el oro, oro rosa, y plata, para crear acabados únicos y llamativos en joyería. Los diferentes metales se vaporizan y condensan sobre el sustrato de joyería simultáneamente o en capas., dando como resultado una impresionante combinación de colores y texturas.

Beneficios: El revestimiento PVD de metales mixtos ofrece infinitas posibilidades para personalización y permite a los diseñadores de joyas crear piezas verdaderamente únicas.

Conclusión

En este articulo, Has aprendido el significado del recubrimiento PVD en joyería y su principio de funcionamiento.. El recubrimiento PVD en joyería revoluciona la estética y la durabilidad y cuenta con una notable resistencia al rayado, retención de color vibrante, y brillo duradero. Con su capacidad de fusionarse molecularmente con el sustrato metálico., El revestimiento PVD garantiza que las joyas sigan siendo visualmente impresionantes y resistentes a los rigores del uso diario., ideal para coleccionistas de joyas.

Preguntas más frecuentes

1. ¿El recubrimiento PVD desgasta las joyas??

No, El revestimiento PVD es muy duradero y resistente al desgaste., proporcionando protección duradera a las joyas. A diferencia de los métodos tradicionales de enchapado, El recubrimiento PVD forma una fuerte unión con el sustrato., asegurando que permanezca intacto y mantenga su brillo incluso con el uso regular.

2. ¿Cuánto durarán las joyas con revestimiento de PVD??

En condiciones típicas de desgaste, Las joyas recubiertas de PVD pueden mantener su apariencia durante 2-5 años, aunque puede aguantar hasta 10 años o más con el cuidado adecuado y una limpieza ocasional.

3. ¿El recubrimiento PVD es oro real??

No, El recubrimiento PVD no es oro real. Es un proceso donde una fina capa de metal, como el nitruro de titanio, Se deposita sobre la superficie de las joyas mediante un proceso de deposición al vacío.. Esto le da a las joyas una apariencia dorada pero no contiene oro real..

4. ¿Se empaña el revestimiento PVD??

El recubrimiento PVD es generalmente resistente al deslustre en comparación con otros recubrimientos metálicos.. Sin embargo, La exposición prolongada a productos químicos agresivos o abrasivos puede hacer que el recubrimiento se degrade con el tiempo..

5. ¿Son seguras las joyas chapadas en PVD??

Sí, Las joyas con baño de PVD se consideran seguras de usar. El proceso consiste en depositar una fina capa de metal sobre la superficie de la joyería., creando un recubrimiento hipoalergénico. Se usa comúnmente en implantes médicos y equipos de procesamiento de alimentos., indicando su seguridad para su uso en joyería.